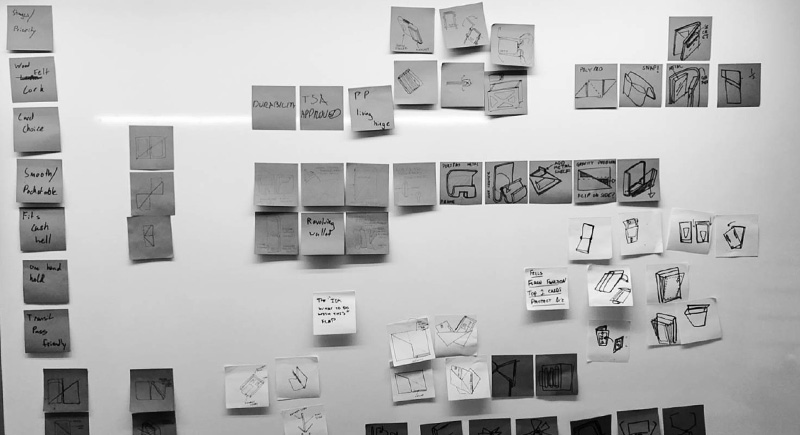

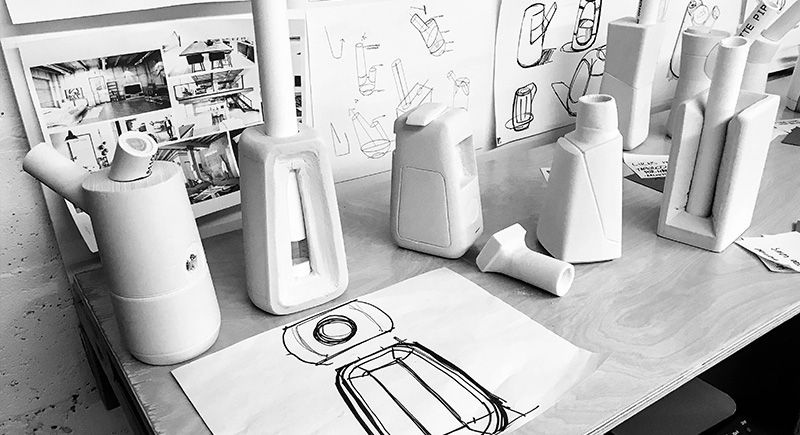

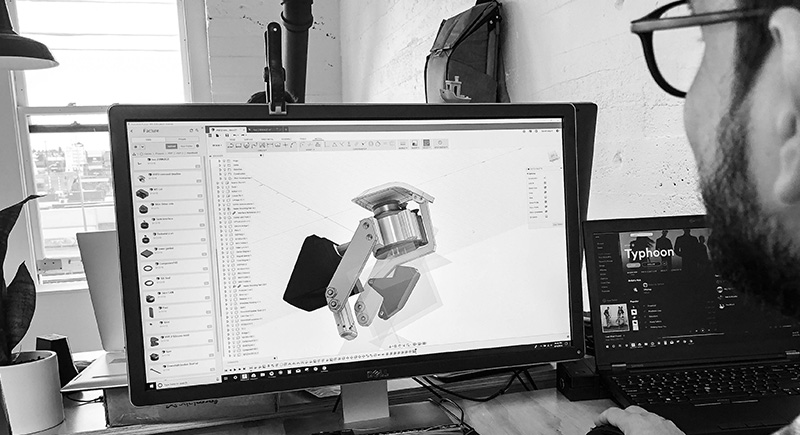

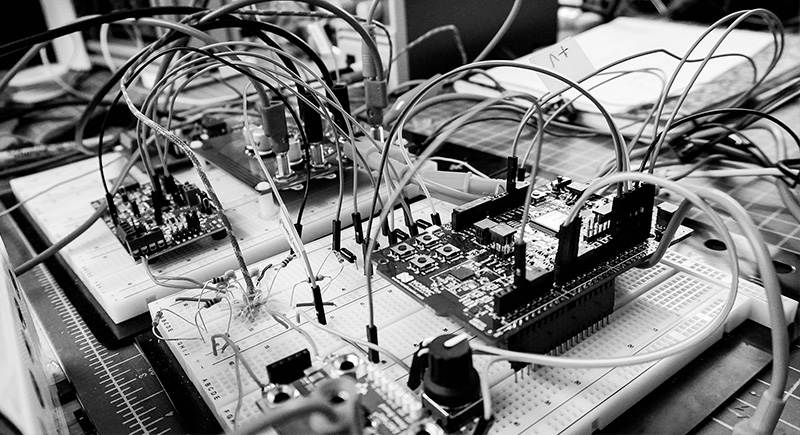

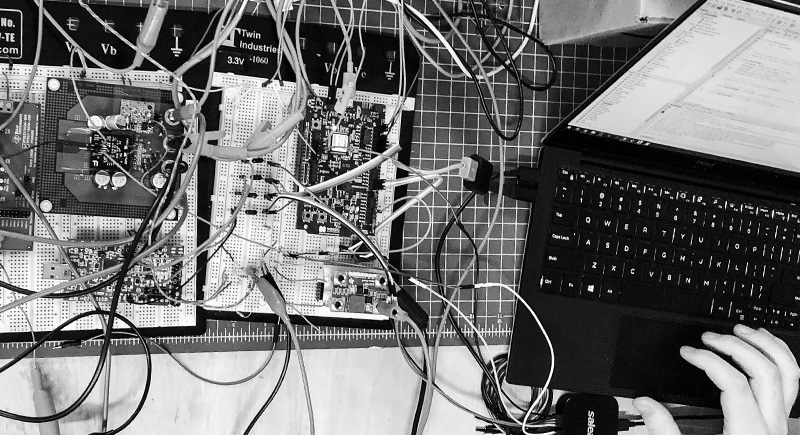

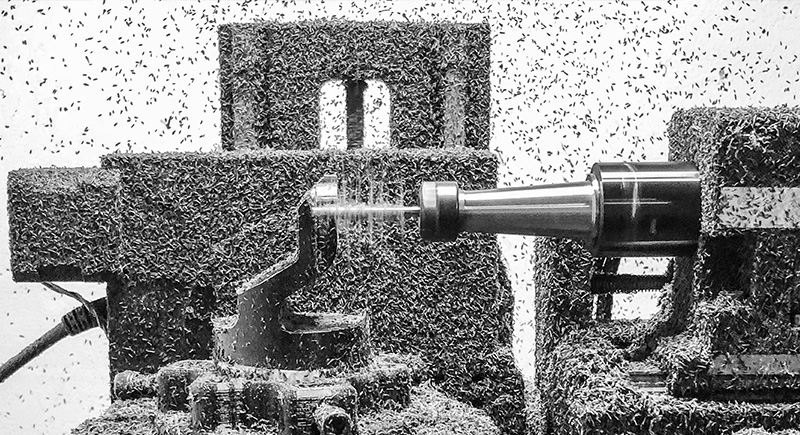

/ Every project is a unique journey, but the framework for success remains largely the same. First, discover what already exists, seek proof of concept and define success. Then, develop and test solutions to prove out functionality before taking the step to integrate the disparate elements into a cohesive embodiement. Finally, refine the details through testing and analysis until ready to realize the vision through production or deployment.